Katalytikertagung 2022: Glatt Particle Design of Cataytic Powder

Weimar, 27.06. – 29.06.2022

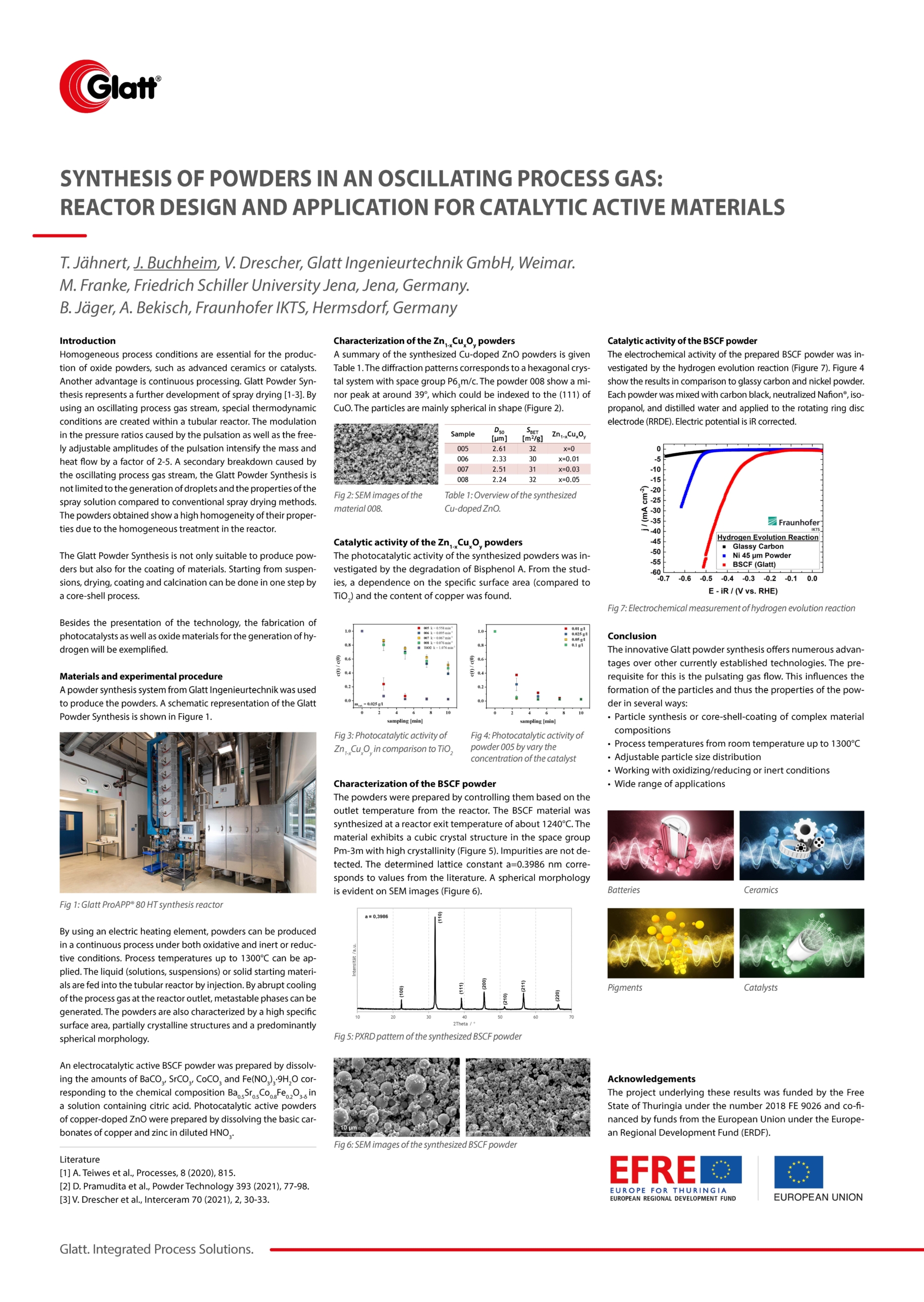

Synthesis of powders in an oscillating process gas: Reactor design and application for catalytic active materials

Homogeneous process conditions are essential for the production of oxide powders, such as advanced ceramics or catalysts. Another advantage is continuous processing. Glatt Powder Synthesis represents a further development of spray drying. By using an oscillating process gas stream, special thermodynamic conditions are created within a tubular reactor. The modulation in the pressure ratios caused by the pulsation as well as the freely adjustable amplitudes of the pulsation intensify the mass and heat flow by a factor of 2-5. A secondary breakdown caused by the oscillating process gas stream, the Glatt Powder Synthesis is not limited to the generation of droplets and the properties of the spray solution compared to conventional spray drying methods. The powders obtained show a high homogeneity of their properties due to the homogeneous treatment in the reactor.

The Glatt Powder Synthesis is not only suitable to produce powders but also for the coating of materials. Starting from suspensions, drying, coating and calcination can be done in one step by a core-shell process.

Besides the presentation of the technology, the fabrication of photocatalysts as well as oxide materials for the generation of hydrogen will be exemplified.

Copyright: Glatt

Copyright: Glatt Copyright: Glatt

Copyright: Glatt