Particle Design with Glatt Powder Synthesis

Discover the wide range of particle design options for innovative high-performance materials. Glatt powder synthesis is a thermal process for processing, generating or coating powder materials. A strictly controlled pulsating and tempered gas flow provides unique flow dynamics. Pulsating gas flows do not exhibit undesirable temperature and velocity gradients due to the high degree of turbulence. Refering to this, classical thermal processes with laminar gas flows, such as rotary kilns or spray towers, are at a disadvantage.

Particle design by spray calcination with Glatt powder synthesis

Micro- and nanopowders are used in many areas today. Due to their high specific surface area, these powders exhibit very high reactivity, leading to better catalytic properties or lower sintering temperatures, for example. The high flexibility of the composition of dissolved raw materials in combination with the extremely high cooling gradients after synthesis, enables the extraction of powders with phase states beyond thermodynamic equilibrium, which also often exhibit improved properties compared to the equilibrium state.

In particle design with Glatt powder synthesis, process steps such as drying, particle formation and calcination are combined in a single step.

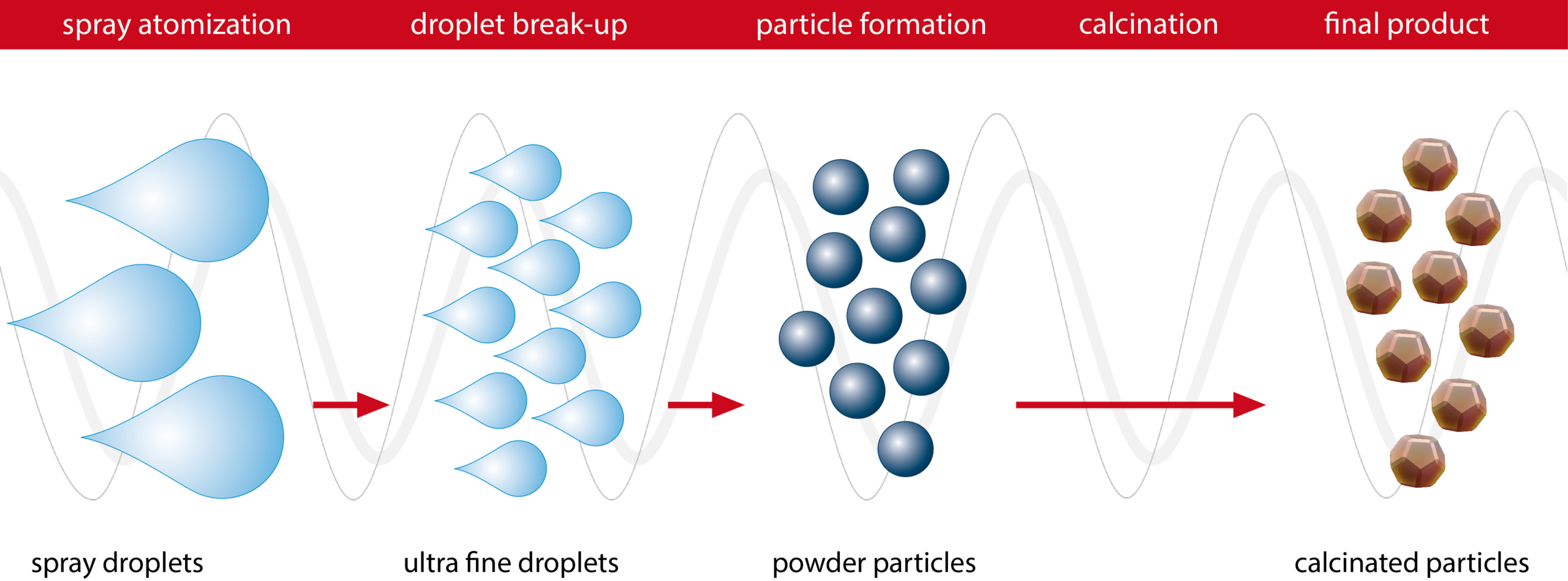

In powder production using Glatt powder synthesis, all particles undergo the same thermal treatment:

- Spraying a raw material solution into the gas stream produces small droplets.

- Pulsating gas flow produces even smaller droplets by secondary droplet decomposition

- Evaporation of the solvent very quickly forms solid powder particles from the droplets

- Optionally, the powder can be thermally posttreated (e.g. calcined) with appropriate temperature control

Coating of nano- and micropowders

Glatt powder synthesis is also used as a process for the production of core-shell particles – coated micro- and nanopowders. For this purpose, suspensions are used as raw materials. By using organic solvents and low process temperatures, temperature-sensitive coating materials (e.g. polymers) can also be applied. At the same time, reactor temperatures of up to 1300°C also allow the core material and coatings to be chemically fused to produce novel composite materials.

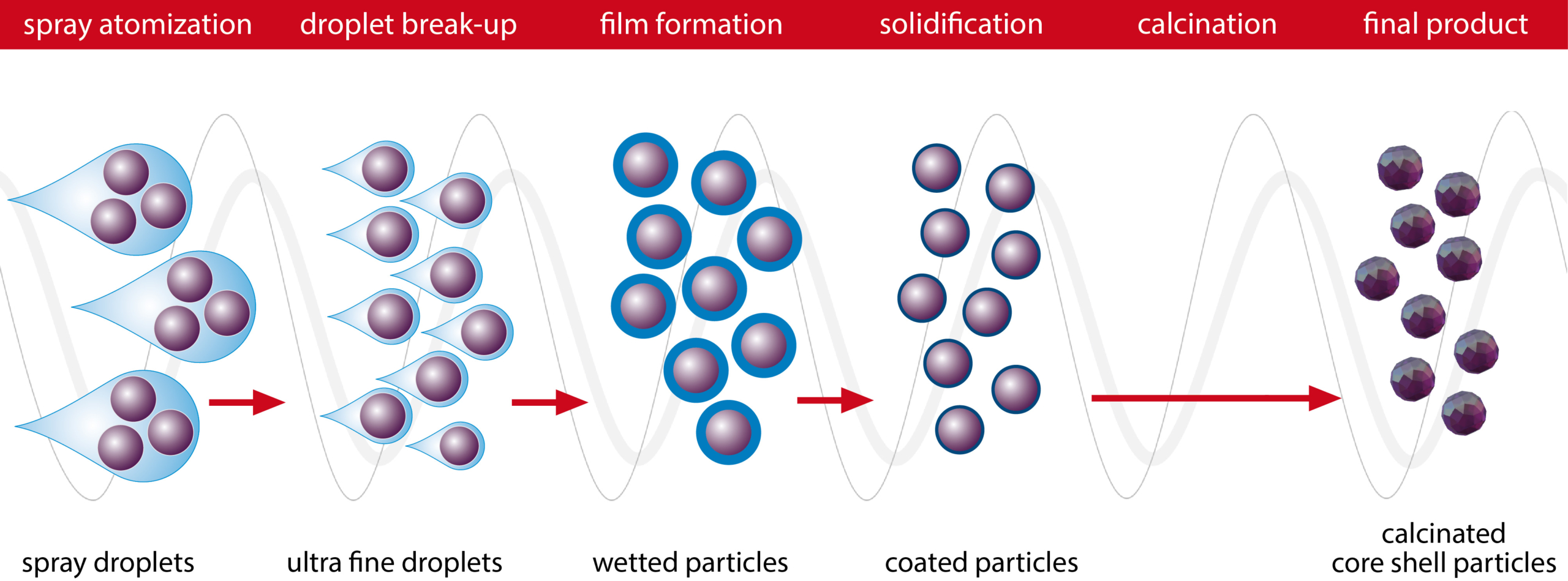

Suspensions are sprayed during coating. The coating material is dissolved and dried onto the core material and is subsequently thermally treated, i.e. calcinated.

Coating with Glatt powder synthesis at a glance:

- The spraying of fine droplets of a raw material suspension into the gas stream.

- The pulsating gas flow breaks these down into even smaller droplets

- The solvent starts to evaporate and wets the particles

- Coated powder particles are formed by evaporation of the solvent

- Optionally, the powder can be thermally posttreated (e.g. calcined) if the temperature is controlled appropriately.

Typical applications of this technique are in the field of pigments and catalytic powders, but also increasingly in energy materials. The applied coating can be used as a protective layer or introduce new functions.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’ PDF, English

Published article: ‘From Hot Gas Stream to Matt Finish by Glatt Powder Synthesis’ PDF, English

June 2021: ‘Fraunhofer IKTS operates world’s first flameless high-temperature powder synthesis plant’