Fraunhofer IKTS operates world’s first flameless high-temperature powder synthesis plant

The German Fraunhofer Institute for Ceramic Technologies and Systems IKTS relies on technology from Glatt to produce high-purity, high-performance oxide materials

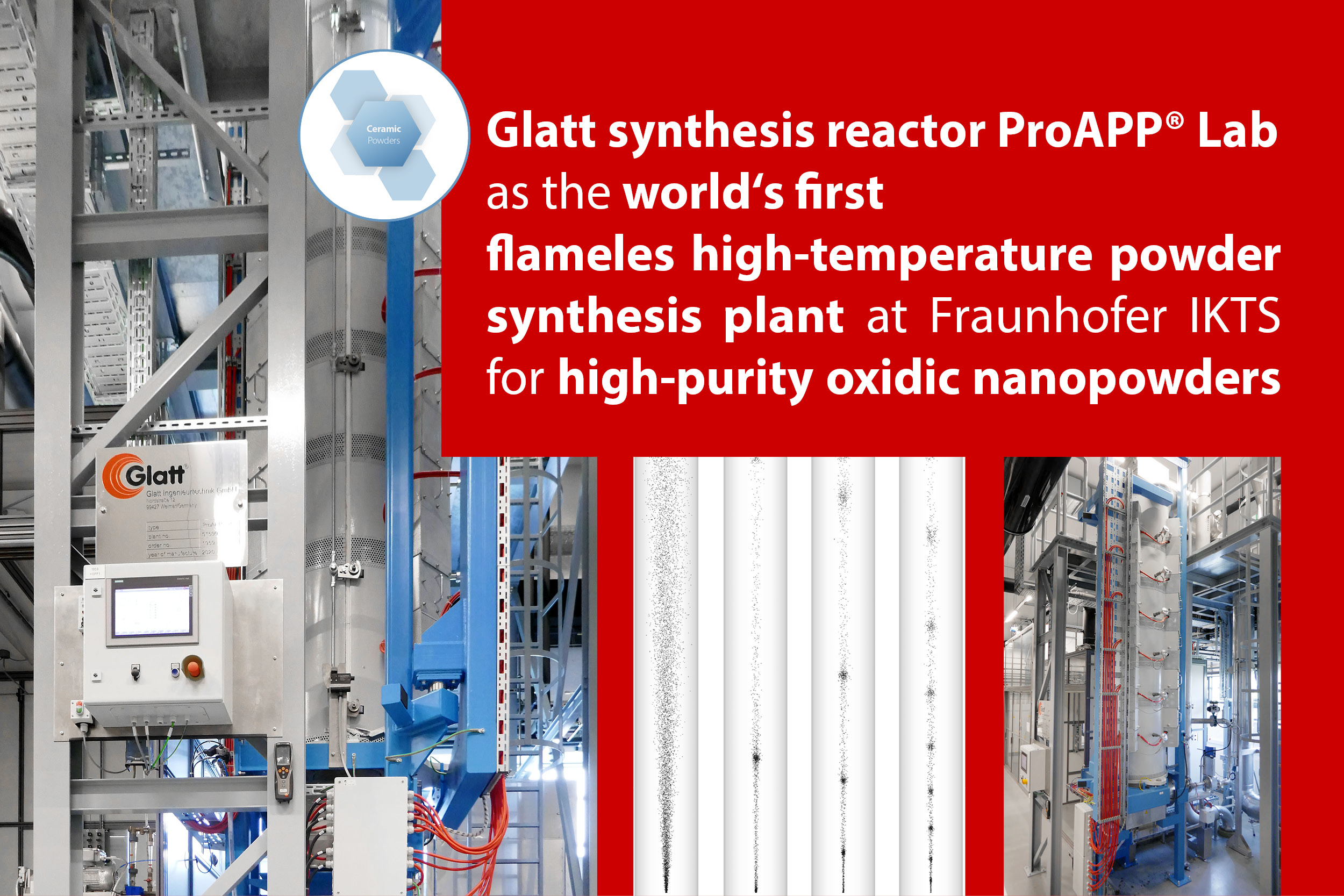

At its Hermsdorf site, the Fraunhofer Institute for Ceramic Technologies and Systems IKTS creates high-performance oxide ceramics for medical technology and optical components. The world’s first Glatt synthesis reactor for temperatures up to 1300°C was recently put into operation there, with the powder synthesis process based, for the first time, on a flameless concept with pulsating gas flow.

Ceramic high-performance materials play a fundamental role in almost all forward-looking industries: mechanical engineering, automotive engineering, electronics, energy, biotechnology and medical technology are just some of the sectors in which IKTS conducts research. For the production of application-specific oxide nanopowders, the researchers now use the powder synthesis technology of plant manufacturer Glatt to produce powders on a kilogram scale (funded by the Thüringer Aufbaubank (TAB), FKZ: 2017 FGI 0038 and co-financed with ERDF).

The technology combines spray drying and spray calcination processes, and enables the precise design of new powder types with precisely adjusted properties in a pulsating gas flow. A reactor heater was installed in the Glatt ProAPP synthesis reactor, which ensures a constant gas temperature of up to 1300°C throughout. This powder synthesis process makes it possible to specifically define the phase state, morphology, grain size and grain size distribution of the primary particles, and produce them to a consistently high quality.

Copyright: Springer Fachmedien Wiesbaden GmbH

Copyright: Springer Fachmedien Wiesbaden GmbH