Glatt Ingenieurtechnik celebrates continued business success with third expansion of its Technology Center

New services, capacities, employees: plant engineering expert Glatt Ingenieurtechnik marks its 30th anniversary with an investment in the future of its headquarters

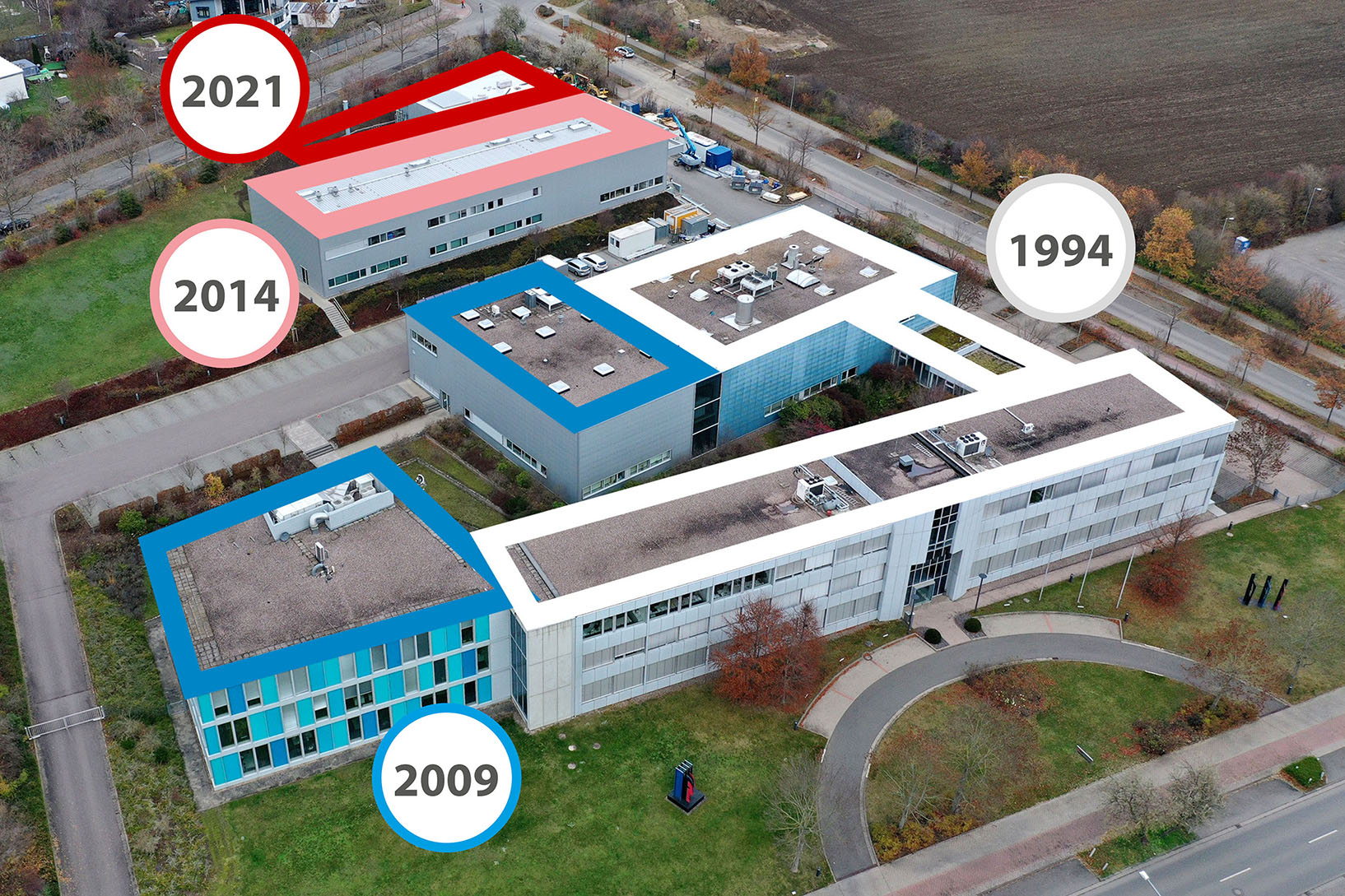

From vitamins in animal feed and enzymes in detergents to powder materials for high-performance batteries, Glatt, the Germany-based plant manufacturer and process expert, is working on all of these in close cooperation with renowned research companies. In spring 2021, Glatt will expand its technology center in Weimar for the third time in twelve years.

Precision landing: Special plant engineering

For more than three decades, Glatt Ingenieurtechnik has been by its customers’ side, from laboratory through to production. These collaborations sometimes lead to ground-breaking new systems that have never previously been considered or designed. Some of these are available at the company’s headquarters in Weimar, which is why the plant manufacturer has expanded its technology center several times in recent years.

The latest developments include, for example, a fluid bed system made entirely of glass for processing special materials with the highest purity demands or for handling corrosive process media. There is also a fluid bed system that processes powders in temperatures up to 900°C, and a synthesis reactor that produces ultrafine powders in the nanometer and micrometer range in a pulsating gas stream, coats them and/or thermally post-treats them at a temperature of up to 1,300°C.

6 million euros new investment for technology expansion

With this being the third expansion since 2009, Glatt is on track for another successful year and, on its 30th anniversary, can look back on 12 months of exceptional achievements – despite the pandemic. The new investment of around 6 million euros will also create jobs and strengthen Thuringia as a business location. At the same time, the new building consolidates the involvement of the Weimar-based experts in numerous projects in the field of cutting-edge research funded by the German Federal Ministry of Education and Research (BMBF). And increased capacity also means potential capabilities for contract production.

“Times like these are exciting not only for our colleagues who develop processes for manufacturing pharmaceutical, biotechnological and medical technology products for vaccines, insulin, blood plasma, biosimilars and active pharmaceutical ingredients (API),” says Sales Manager Lutz Heinzl. “We are also experiencing a strong increase in demand for processes related to particle design and particle engineering.”

Here, the focus is, for example, on the development, optimisation and functionalisation of bulk materials such as powders, granules and pellets for ingredients and additives in food and nutritional supplements or pet food, detergents, fertilisers, pesticides or industrial salts. In addition, Glatt engineers research and work on materials for high-performance batteries, 3D printing, paints and coatings, ceramics, catalysts and many other chemical and fine chemical products.

From the initial idea to turnkey production

Glatt accompanies its customers through the entire process – as a service provider or development partner in individual project phases through to general planner or contractor. As an innovative provider of complex, integrated solutions, Glatt advises on, plans and implements projects worldwide – from the expansion or modernisation of existing production facilities to the construction of entire new factory plants. The integrated service concept promises sustainable process and factory planning with cross-industry plant engineering, adapted to customers’ individual technology requirements with in-house process engineering or licensed solutions, supplemented by services for rapid market access.

As a pioneer in fluid bed and spouted bed technology, as well as patented powder synthesis in a pulsating gas stream, Glatt has many years of experience in pioneering process solutions for drying and spray granulation of liquids containing solids, instantisation by spray agglomeration of powders, micro- and matrix encapsulation of active ingredients, synthesis of novel powder systems by spray calcination, and coating/core-shell of nanoscale particles down to grain sizes in the millimeter range.

Champion among engineering companies

Through global demand and an excellent scientific network, the plant engineering company is researching the materials and production processes of the future. Glatt is a member of various regional innovation initiatives funded by the BMBF and maintains close links with scientific institutions, including the Bauhaus University in Weimar, Otto von Gericke University in Magdeburg and the Technical University of Hamburg Harburg. The ministries of economics, state development agencies and investment banks of the eastern German states and Berlin have lauded Glatt Ingenieurtechnik as a champion among engineering companies in eastern Germany. The jury of the business magazine WIRTSCHAFT+MARKT selected Glatt as one of the 150 most innovative companies from seven sectors in 2019.

Sustainability is one of the company’s core values

With its innovative PHOS4green recycling process, Glatt is making a decisive contribution to environmental protection. The vital element phosphorus is recovered from sewage sludge ash and converted into ready-to-use fertilisers. This not only makes domestic phosphate reserves usable, but also provides alternatives to mineral fertilisers – even with reduced heavy metal content.

From 20 employees to a global player

The roots of Glatt Ingenieurtechnik go back to the “Continuous Fluid Bed” working group founded in 1981 at a Weimar research institute of the Magdeburg Heavy Machinery Combine “Ernst Thälmann” (SKET). Two years later, the first production plant for continuous granulation drying of feed yeast was put into operation. After the reunification of Germany, contact was established with the Glatt Group. Founded at the turn of 1990/1991, Glatt Ingenieurtechnik expanded the Group’s expertise to include a technology centre for innovative fluid bed processes and turnkey factory planning.

Dr. e. h. Reinhard Böber, Managing Director from the start, is still at the helm of the former 20-person company which has since become a successful global player. In this environment, young engineers, prospective graduates and trainees start their careers alongside experienced employees. In 2020 alone, Glatt Ingenieurtechnik hired 25 new employees. Modern, well-equipped workplaces, flexible working hours, regular training and development opportunities, company health and pension schemes, and a company canteen characterise Glatt as a modern employer in an attractive social and cultural environment. A company kindergarten has also been offering permanent places since October 2019.