Catalysts powder with exceptional activity for high-performance applications

Catalysts powder materials always act selectively and application-specifically. Their application possibilities are almost unlimited, because catalysis is a key technology in the chemical industry. It is therefore a great challenge to develop catalysts materilas suitable for the respective industrial application and to bring them to market maturity.

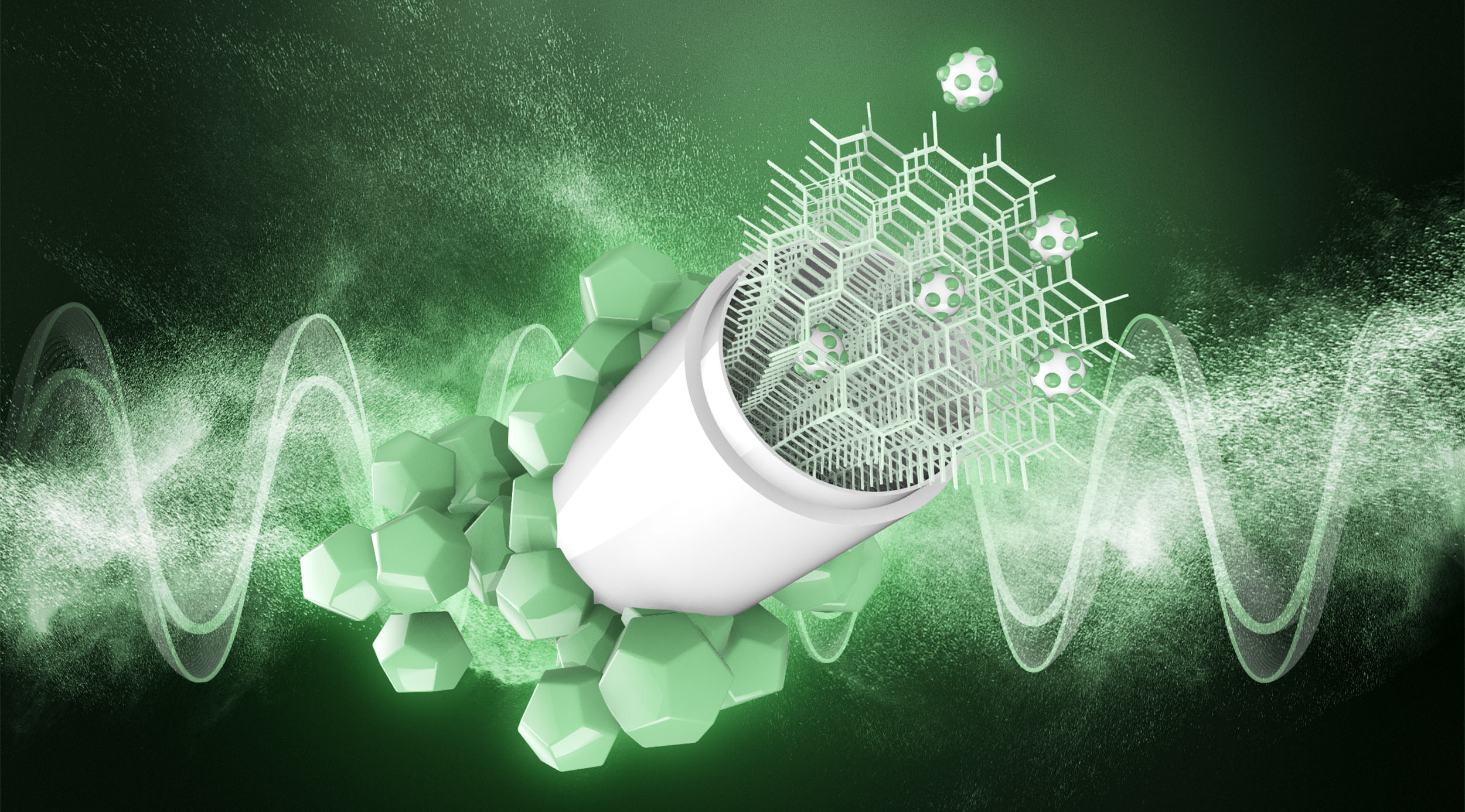

Production in constant quality and larger quantities is demanding. Previous processes still require long development times before catalysts can be produced on an industrial scale. Glatt powder synthesis opens up new avenues. For the first time, the innovative pulsating spray calcination process enables the rapid, precise and application-specific production of catalysts powder.

In a single process step, the chemical composition, the size of the catalytic powder particles and the particle structure and surface are precisely generated. The activity of the catalytic powder materials can be precisely adjusted, for example by defining the properties of the surfaces for specific applications. The respective application determines the procedure and in a short time the catalysts powder materials reach the required activity level.

The unique thermodynamic conditions in the pulsating and thus turbulently mixed hot gas flow make it possible to achieve special reaction states in fractions of a second. These lead to extraordinary properties and, for example, allow the catalytic activity to be increased many times over.

The advantage of the strongly pulsating flow is the up to 5 times faster heat transfer from the gas to the particle. We use these thermodynamic possibilities, for example, to create catalysts powder materials with amorphous structures and high lattice defects. This significantly increases their catalytic activity. In addition, Glatt powder synthesis offers the possibility of adjusting the gas atmosphere oxidizing or free of oxygen. Another important parameter for the targeted synthesis of the desired catalytic powder materials.

The homogeneity of the powder is very important for the development of catalysts. Glatt powder synthesis allows the use of raw material solutions that contain all components of the desired material in an optimal mixture. This chemical homogeneity of the raw materials in combination with the identical thermal treatment guarantees an outstanding quality of the catalysts powder coating.

Glatt Powder Synthesis – Our efficient solution for the development of your customized catalytic powder materials.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’ PDF, English