Novel manufacturing process for highly permeable oxygen membranes and development of an innovative membrane connection plate for oxygen generators

The “SaMBa” project was based on the use of the new material BSCF (Ba0,5Sr0,5Co0,8Fe0,2O3-x), which was to be optimized for O2 separation by adapting the particle morphology to subsequent processing into membrane components. The goal was to minimize the grain size to produce the thinnest possible membrane after sintering as thinner membranes increase O2 permeability. In addition, it was to be investigated how BSCF waste – such as processing residues – can be recycled through treatment processes. The operating behavior of the entire system equipped with O2 membranes was recorded experimentally and simulated in parallel by FEM.

The aim was to determine suitable operating conditions for the permanent, efficient and safe operation of O2 membrane systems and also to identify suitable peripheral components for a connection plate suitable for series production, on the basis of which larger membrane systems can be designed.

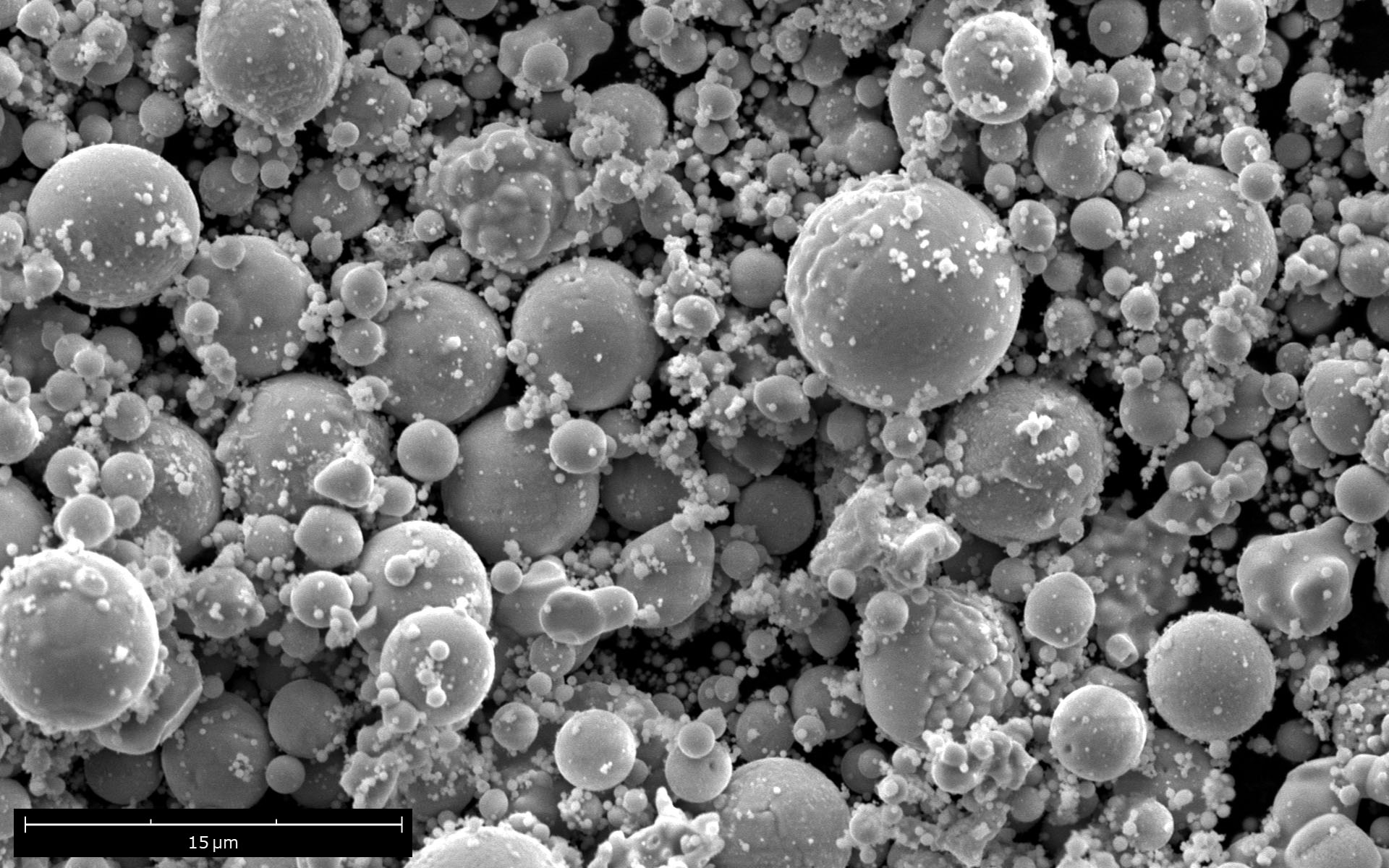

As part of the “SaMBa” project, Glatt used Powder Synthesis to produce the raw material powders in the appropriate particle size and phase composition for use in further process steps. In comprehensive synthesis tests, the specific influences of the process parameters on particle formation were investigated. It was shown that both the frequency and the spray pressure influence the particle properties with regard to particle size, particle size distribution and yield. With regard to the chemical conversion of the mixed oxides, it was found that this can be directly influenced by the process temperature as well as the pulse amplitude and its combination with the frequency.

Synthesized BSCF powder

Partners:

- Fraunhofer-Institut für Keramische Technologien und Systeme (IKTS)

- Tisoma GmbH

- Glatt Ingenieurtechnik GmbH

The project “SaMBa” is funded by the Free State of Thuringia as part of the joint project 2018 VF 0011 from the European Regional Development Fund (ERDF) and co-financed by the European Union.

Funding code of the Thüringer Aufbaubank for the sub-project of Glatt in the joint project “SaMBa” 2018 FE 9026

Duration: 10.12.2018 – 31.05.2022

Cost-efficient synthesis processes for the production of BSCF powder systems in a pulsating gas flow (Poster)

“SaMBa” research project: Novel manufacturing process for highly permeable oxygen membranes and development of an innovative membrane connection plate for oxygen generators

“Mixed ionic electronic conductor” (MIEC) membranes are specialized inphase materials which exhibit significant electron and ionic conductivity. Therefore, neutral molecules can be transported through a solid membrane and thus separated from other components. One such material is BSCF (barium-strontium-cobalt-iron oxide), which enables efficient oxygen exchange. The production of BSCF by Glatt Powder Synthesis and the efficiency of the produced membranes was the focus of this research.

Further information on this topic and related topics can also be found in the following publications:

Published article: ‘Ceramic Raw Materials from the Pulsating Hot Gas Stream’ PDF, English

Published article: ‘New Battery Material by Powder Synthesis’ PDF, English

Published article: ‘Glatt Powder Synthesis – Pioneering Process for Groundbreaking Particle Synthesis’ PDF, English